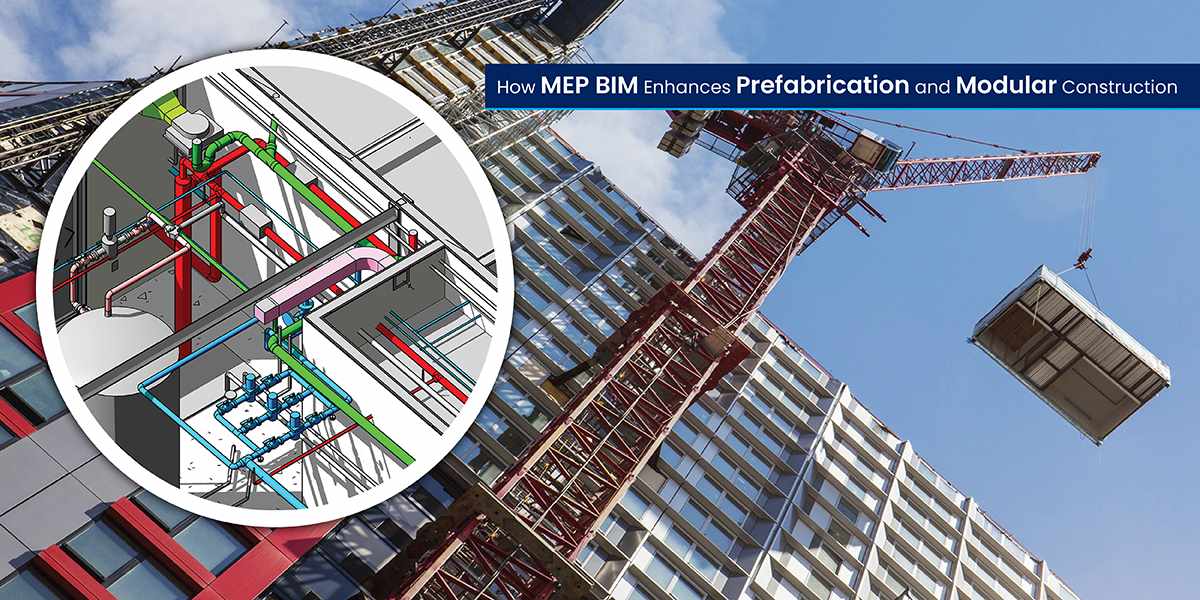

MEP BIM prefabrication and modular construction improve design accuracy and efficiency by including MEP systems in pre-manufactured equipment. This reduces on-site issues, improves fabrication, and expedites MEP assembly, ensuring quick project completion and cost savings.

Project teams often struggle with mechanical, electrical, and plumbing (MEP) systems when working without proper BIM workflows. These challenges primarily affect visualization, collaboration, and compliance verification during construction phases. This leads to coordination difficulties, increased errors, and inefficient resource management, particularly in prefabrication and modular construction. Critical MEP components like HVAC, power distribution, lighting, and water supply systems become especially vulnerable to these issues, impacting both building functionality and occupant comfort.

MEP BIM implementation offers a comprehensive solution through accurate, data-rich modeling capabilities. Digital models and integrated workflows enable MEP designers, engineers, and prefabrication professionals to collaborate effectively. Remote manufacturing and installation processes can be better supported through this technological approach.

The benefits of MEP BIM integration extend throughout the project lifecycle. Teams can achieve smoother design coordination and streamlined installation processes. System interference can be significantly reduced while resource allocation becomes optimized. Enhanced visualization and collaboration capabilities allow for more efficient sequential planning and fewer errors. Prefabrication teams can work more effectively with accurate, coordinated system models, benefiting both off-site manufacturing and on-site installation processes. Project timelines can be accelerated through these combined improvements, creating a more efficient construction workflow.

Understanding MEP BIM

MEP BIM coordinates mechanical, electrical, and plumbing systems into a collaborative 3D model. Advanced BIM techniques for MEP prefabrication include real-time collaboration, accurate quantity takeoffs, and system simulations. MEP BIM clash detection for modular builds reduces errors and improves design efficiency for the entire project phase.

Legacy MEP design depends on sketches, 2D drawings, and manual calculations, which lead to problems. MEP BIM prefabrication uses an accurate and data-rich 3D model, facilitating real-time updates, coordination, and automated calculations to enhance accuracy and efficiency.

Common MEP BIM tools used by MEP designers, engineers, and prefabrication professionals include Revit, AutoCAD MEP, Navisworks, and BIM360. These tools support 3D modeling, simulation, and documentation of MEP equipment while also providing capabilities like system analysis, data integration, and clash detection.

The role of MEP BIM in prefabrication

BIM in MEP systems ensures accurate, coordinated, and effective prefabrication of MEP equipment by generating coordinated and clash-free 3D models and fostering streamlined collaboration between various teams.

BIM for prefabricated MEP construction refers to the manufacturing of MEP building elements at remote and controlled locations. These components are moved and assembled on-site, leading to faster construction, improved quality, and a reduction in labor costs. This methodology reduces on-site issues and delays while improving project efficiency.

How MEP BIM supports the design, fabrication, and assembly of prefabricated systems

Digital modeling for MEP prefabrication helps the entire workflow through the conversion of 2D drawings and hand-drawn sketches into coordinated and clash-free 3D models of MEP systems. Prefabrication driven by BIM ensures every component fits and functions correctly. During the prefabrication process, MEP BIM data is used to create precise parts with assembly instructions to reduce rework and errors. Since components are built offsite, it becomes easier for the assembly team to follow clear and accurate instructions to ensure faster project completion.

Benefits of using MEP BIM for prefabricated MEP systems

BIM prefabrication benefits for modular buildings include improved precision in MEP system design and equipment manufacturing. The coordinated and clash-free 3D model ensures every part is manufactured as designed and fits together as planned. It reduces the risk of errors, accelerates construction schedules, improves quality control, and enhances resource allocation to reduce project costs for MEP firms.

MEP BIM in modular construction

Revit BIM for MEP modular systems optimizes the design and integration of mechanical, electrical, and plumbing equipment to ensure accuracy and efficiency.

Modular construction and its growing popularity

MEP BIM modular construction involves generating pre-assembled MEP units in a controlled space. These MEP systems are transported on-site for final assembly. The use of modular construction has risen due to its capability to reduce construction time, deliver cost savings, and provide consistent quality. Prefabricated modular construction using BIM is suited for large projects like schools, residential and commercial buildings, offering quick completion and higher sustainability.

How MEP BIM enhances the planning and integration of MEP systems in modular units

MEP BIM uses accurate parametric modeling of MEP systems to create modular units. This helps in quick integration of systems into prefabricated designs. Leveraging accurate, data-rich, and real-time 3D MEP models created in Revit and checked in Navisworks for clashes helps engineers improve space allocation, system routing, and the placement of equipment. Automated interference detection and validation driven by BIM tools flag and resolve clashes between architectural, structural, and MEP systems. This lowers the need for frequent on-site modifications. It also ensures every building member is coordinated before actual assembly begins.

Streamlining the coordination between modular units and MEP systems

MEP BIM refines coordination by unifying project data, enabling real-time updates and facilitating real-time communication between project participants. BIM’s capability to monitor and visualize the spatial integration of MEP equipment across modular systems ensures every element is compatible before it is transported on-site. During assembly, 3D BIM models are invaluable references for erection personnel to ensure accurate installation and to reduce site changes. Automated documentation and management of materials enable enhanced logistics, which ensure prefabricated elements, including MEP systems, meet required specifications and are delivered within timelines.

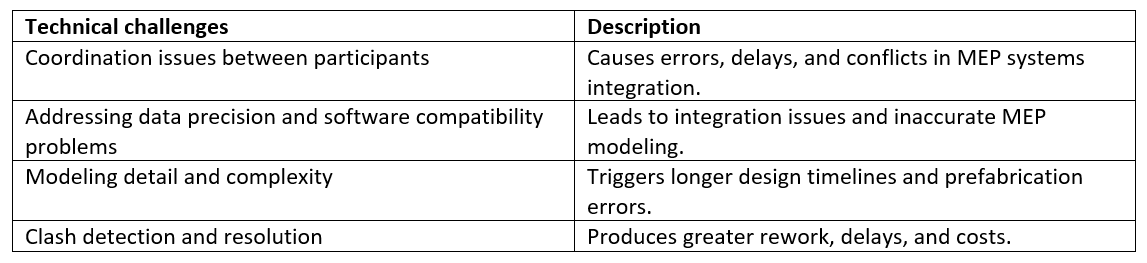

Challenges in implementing MEP BIM for prefabrication and modular construction

Implementing MEP BIM prefabrication and modular construction can present challenges, such as data interoperability, the requirement of skilled expertise, and resistance to change from legacy construction methodologies.

How AI and automation would improve MEP prefabrication and modular construction

AI and automation are set to transform MEP prefabrication and modular construction by using advanced algorithms to optimize design and achieve predictive analytics. AI-based tools can perform real-time simulations, prevent inconsistencies, and automate the clash detection process to enhance system integration.

Fabrication automation with robotics and CNC machines will ensure greater accuracy and consistency in MEP equipment production. AI-driven MEP systems will help MEP designers, engineers, and prefabricators improve resource and material management, reduce waste, and expedite on-site assembly.

Conclusion

Incorporating MEP BIM into modular and prefabricated construction improves design accuracy, expedites project schedules, and refines coordination. Integrating MEP systems into prefabricated MEP elements mitigates on-site problems, reduces errors, and improves resource management. With the growing use of automation and AI, MEP BIM will transform construction while providing higher precision, productivity, and cost savings.

Write a comment ...